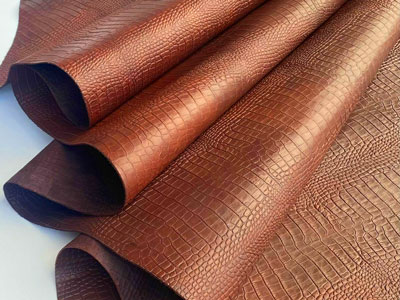

Leather Chemical Products

For the Beamhouse and Tanyard

- GBanti-Bacteria as a Biocide and Fungicide:

Prevents the growth of bacteria which can damage the hides or skins during the soaking process.

- GBdetergent 3D / GB Conc as a Surfactant:

Used for the wetting of the back of hides and skins.

- GBdetergent STRM/ High conc as a Degreaser:

Helps remove natural fats and grease from hides and skins.

- GBdetergent SRM CONC / NF conc as a Swell-regulating agent AND Liming auxiliary:

Helps prevent uneven swelling/wrinkling of the hides or skins during liming through chemical penetration.

- GBlanon fixer as a low sulphide unhairing agents:

Reduces the amount of sulphides used in a tannery and with it, reducing its environmental impact.

- GBalkaline buffer as a replacement for soda ash and sodium bicarbonate:

Raises the pH of the hides or skins during the soaking or liming process.

- GBcid AS as sodium formate and as an organic-acid deliming chemical:

Helps raise the pH during the neutralization process and replaces traditional ammonium salts when deliming hides and skins therefore helping reduce the ammonium salt pollution in tannery wastewaters.

- GBacrylic retarder as a replacement for salt:

Used during the pickling process to prevent acid swelling of the hides or skins.

- GBkol MSD / GBsequestering TAs as a salt-free pickling chemical:

Replaces traditional pickling-salt and greatly reduces salts in tannery wastewaters.

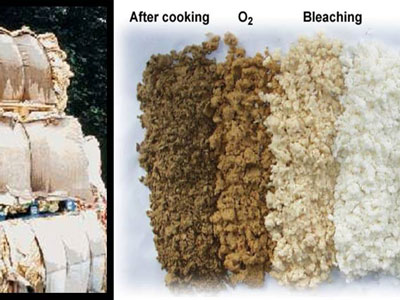

- GBbleaching powder/ GBscour KB as an aldehyde tanning agent:

Makes wet white.

- GBdensol FM as a replacement for magnesium oxide and GBalkaline buffer as a replacement for sodium bicarbonate:

Both raise the pH of the hide during the basification process and allows chromium or aldehyde to chemically bind to skin or hide protein.

Dyehouse

- GBdetergent SRM CONC as a surfactant/wetting agent:

Reduces the wetting back time and also help clean the wet blue or wet white, removing dirt or machine grease or oil .

- GBdetergent 3D / High conc as a degreaser:

Removes fat from tanning machinery on wet blue or wet white.

- GBresin PC as a replacement for (Butadiene) resin:

For leather finishes like fullness, good lightfastness and coverage and a tight grain to the leather.

- 6 types of GBcopolymers:

- GBcopolymer

- GBcopolymer Plus

- GBcopolymer Soft

- GBcopolymer Hard

- GBcopolymer Hard Tacky

- GBcopolymer Soft Tacky

For fullness, light-fastness and tight grain to leather.

- GBdipersing BL:

For the even dispersion and penetration of dyes.

- GBspinning oil AF/ GBsmooth silicon SES / GBsilicon Exell / GBsmooth silicon Resin SR as fat-liquors:

For softness for the final leather product.

Finishing

- GBrepell HP / 6 types GBcoplymers (see above) as a replacement for acrylic resins:

For an adhesive, water-resistant finish to leather products.

- GBfiller VA/VA plus / 6 types GBcoplymers (see above):

Can fill small blemishes on the surface and prevent sticking to the embossing plate or roller when it is embossed.

- GBwhite paste new as a duller:

For a less shiny and glossy finish.

- GBcross linker eco/D:

Toughens the end product and makes the polyurethane water-repelling effect better.

- 6 types of GBsilicon resins as handle modifiers:

- GBsmooth silicon Resin SR

- GBanti-scratch silicon Resin AR

- GBhydrophilic silicon Resin HR

- GBanti-scratch-smooth silicon Resin ASR

- GBanti-scratch hydrophilic silicon Resin AHR

- GBsmooth-soft silicon Resin SSR

For a waxy, slippery finish and better test performance results.

- 6 types of GBcoplymers (see above) as a replacement for acrylic lacquers:

As a finishing top coat.

- GBret GB/D/ D new as a Polyurethane lacquer and resin:

As a finishing top coat for leather products and for good toughness / light fastness.

- GBsyn thickener GP ( very concentrated thickener) as a viscosity modifier:

For a more viscose finish mixture.

- GBsuper pigments:

Are colouring agents for hiding defects on leather surfacess.

- GBdefoamer E / GBantifoam:

Prevents bubbles from forming in the finish mixture.